By Minco Staff

Measuring the temperature of fluid flowing through a pipe can be critical in a variety of applications. But deploying the necessary sensors can be a challenge. There are several ways to get a sensor into the pipe, but those can be costly and complex, especially if they involve retrofitting an existing system. At the same time, taking a measurement at the surface of the pipe may not be sufficiently accurate using traditional technology, but there is a simple and accurate way to measure fluid temperature without opening the system–using surface-mounted Thermal-Ribbon™ sensors.

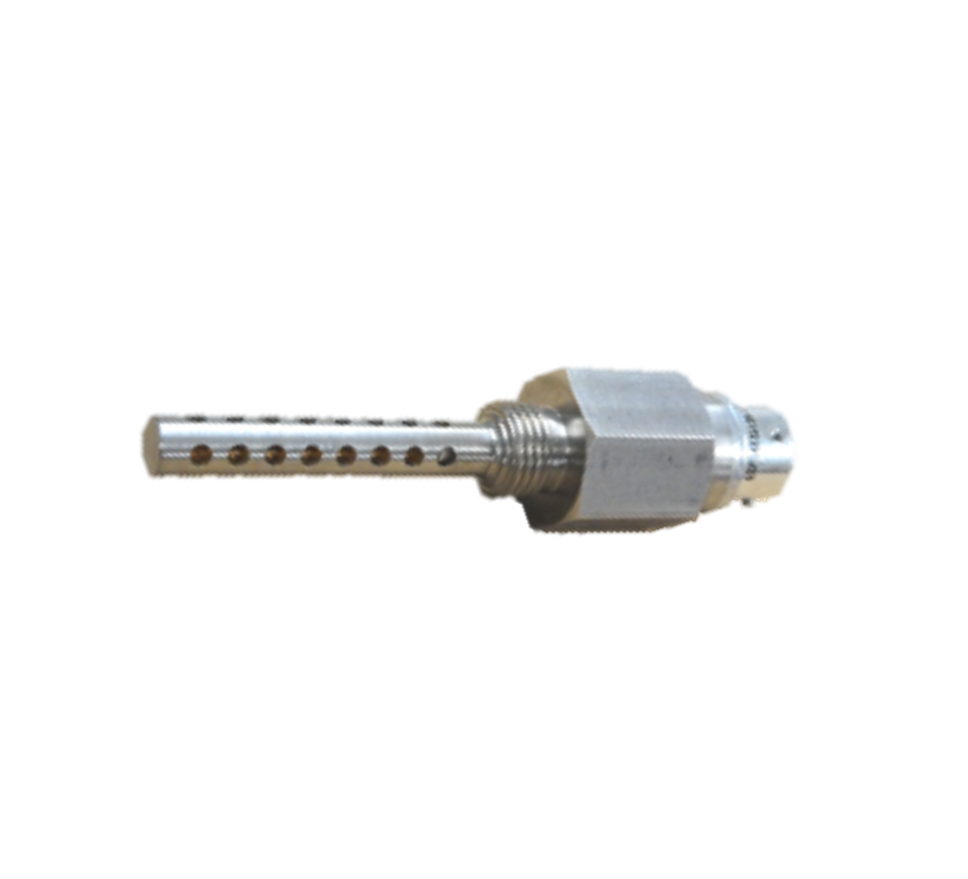

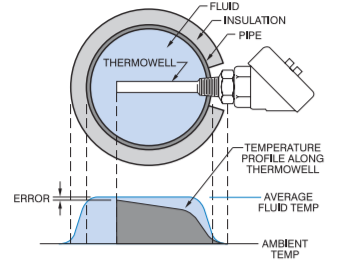

There are two ways to deploy temperature sensors in direct contact with fluid in a pipe. A sensor can be placed longitudinally in the pipe, but that has to be done either when the system is being built or by opening an existing system. These are complex and invasive processes. A second option is to place a thermowell into the system by drilling and tapping a hole in the side of the pipe and inserting a probe that remains in direct contact with the flowing liquid. (See Figure 1) Besides being a complicated and invasive process, installing a thermowell creates a significant break in the insulation around the pipe and provides a metal conduit that draws heat away from the fluid flowing in the pipe.

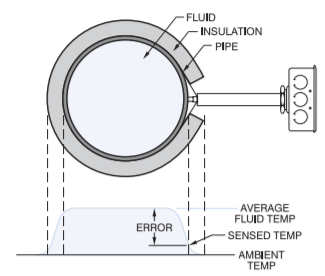

There are surface mounted sensors that can provide non-invasive temperature measurement at a single point on the pipe surface of a pipe. (See Figure 2) The problem with that approach is that, like a thermowell, it creates both a significant break in the pipe’s insulation and a physical conduit drawing heat away from the pipe surface. This approach virtually ensures that the reading at that point will be affected by both radiant and convective heat loss.

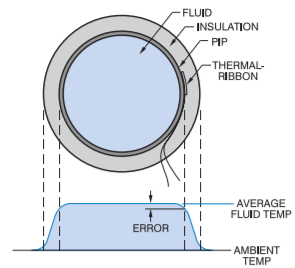

Using a Thermal-Ribbon for surface-mounted temperature sensing is a far simpler solution. It can be as effective as sensing inside the pipe. While the surface of an uninsulated pipe is warmed by the heated fluid and cooled by the ambient air, if the pipe is well insulated, the outside surface of the pipe will be warmed to the same temperature as the fluid. That temperature will, of course, drop within the insulating layer until it reaches the outside air. But thin, flexible Thermal-Ribbon sensors applied directly to the pipe surface under the insulating layer will measure temperature before any of the heat loss takes place. (See Figure 3)

Testing has shown that a Thermal-Ribbon can be just as accurate as a probe within the pipe or a thermowell assembly inserted into the pipe. In testing, surface-mounted ribbons are slower to respond to temperature change than a probe within the pipe, but quicker to respond than the “fast-responding” brass thermowell. Thermal-Ribbon sensors have the significant advantage over both of the alternatives of being easy to apply without opening the system or cutting into the pipe. Simply remove the pipe’s insulation, apply the ribbon to the pipe using pressure sensitive adhesive, stretch tape, or RTV cement, and replace the insulation. Rapid response and easy installation make Thermal-Ribbon sensors an ideal way of measuring the temperature of fluids flowing within a pipe.

Let us help you create a custom solution for your next project!