By John Baichtal

Traditional etched-foil heaters require sensors to ensure the heater reaches its setpoint, and require a controller to manage the heater and maintain a fixed wattage. SmartHeat allows customers to skip this hardware because the patented polymer-based heater’s resistance is dynamic and increases with the temperature of the heater, automatically throttling power as it approaches the setpoint.

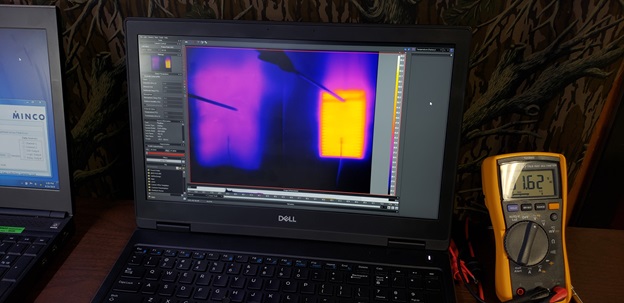

However, SmartHeat has another advantage: it still works when punctured. To illustrate this advantage, Minco’s Thermal Solutions engineers set up a test at a local archery range, where they shot arrows into both etched-foil heaters and SmartHeat heaters, observing the results on a thermal camera.

Watch the video below and then read on to learn more about this advanced product.

The Experiment

Setup consisted of two targets, one with a Thermofoil heater and one with a SmartHeat heater. Adhesive temperature sensors (Minco Thermal Ribbon) were attached the surface of each heater and thermal cameras were positioned to monitor the results. We shot a number of arrows into several heaters to observe the results.

During the experiment, we discovered when targeting dual-element etched-foil heaters it was easy to pierce one conductor and not the other, leaving the heater operating at half capacity. While this may seem advantageous, most heating applications require a specific temperature range and heating only one element corresponds to a proportionately cooler heater. Even worse, traditional etched-foil heaters are susceptible to thermal runaway, where a damaged conductor results in increased current flow leading to the heater burning out and potentially catching fire. We then used broadhead arrows to cut two conductors simultaneously and killed the heater with a single arrow.

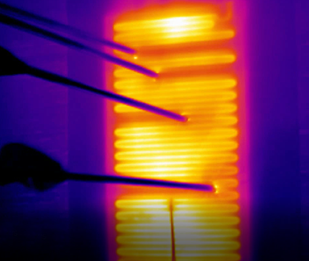

By contrast to the etched-foil heater, the SmartHeat heater suffered minor heat loss during the experiment. When pierced by one or more arrows, it simply heated around the punctures—see the image below. By contrast the etched-foil heater (seen to the right of the picture) began to lose heat immediately after its conductor path was broken.

About Smartheat

SmartHeat consists of a thin silicone matrix loaded with conductive carbon particles. Electrical current moves between the particles via quantum tunneling of electrons through the non-conductive silicone material. The electrical resistance of the material and the current it can carry at any point is determined by the spacing between the carbon particles, and that the spacing changes with temperature. As the silicone warms, thermal expansion drives the carbon particles farther apart and increases resistance point-by-point over the surface of the heater. At the designed set-point temperature the heater effectively becomes an electrical isolator, drawing negligible current, and no longer producing heat. Conversely, if the silicone cools via environmental or load variations, the carbon particles pull closer together reducing resistance. This allows localized increased current flow and the heater to produce more heat at that location as needed to maintain thermal equilibrium. These effects drive the self-limiting nature of this technology without the need for external instrumentation and control systems. By controlling the composition of the carbon-silicone matrix in production, the heater is designed to approach, but not exceed, a specific temperature set point. When the heater is powered, it warms to its designed temperature set point and maintains that temperature within a narrow band.

non-conductive silicone material. The electrical resistance of the material and the current it can carry at any point is determined by the spacing between the carbon particles, and that the spacing changes with temperature. As the silicone warms, thermal expansion drives the carbon particles farther apart and increases resistance point-by-point over the surface of the heater. At the designed set-point temperature the heater effectively becomes an electrical isolator, drawing negligible current, and no longer producing heat. Conversely, if the silicone cools via environmental or load variations, the carbon particles pull closer together reducing resistance. This allows localized increased current flow and the heater to produce more heat at that location as needed to maintain thermal equilibrium. These effects drive the self-limiting nature of this technology without the need for external instrumentation and control systems. By controlling the composition of the carbon-silicone matrix in production, the heater is designed to approach, but not exceed, a specific temperature set point. When the heater is powered, it warms to its designed temperature set point and maintains that temperature within a narrow band.

Once thermal equilibrium is achieved, SmartHeat responds to any changes in the environment to maintain the operating temperature across the entire device surface. When an arrow strikes SmartHeat, it simply adapts. When an etched-foil heater is damaged, uneven heating and thermal runaway may result.

Heaters vs. Punctures

The fragility of etched foil doesn’t just impact its ability to heat. A heater suffering from delamination due to physical damage may also have a difficult time radiating the heat, resulting in possible “hot spots” that can burn through the heater and even cause thermal runaway. For instance, if the application calls for a heater to a heat a container of fluid but the container is suddenly emptied, an etched-foil heater may overheat.

SmartHeat doesn’t have these problems. Not only can it be damaged and still function (see the image to the right) Its dynamic makeup allows it to adapt to rapid changes in the environment. In the case of the empty container, SmartHeat’s would detect the container’s increased heat and its resistance increases to throttle power before thermal runaway can occur. The ability to operate despite damage is only one of SmartHeat’s many advantages. Contact Minco today to learn more about this advanced heating technology and how it can benefit your next application.