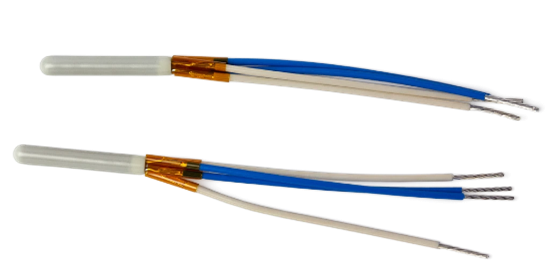

Minco’s Glass-on-Ceramic Wire-Wound RTD Elements offer unparalleled performance for a variety of demanding applications – now available with shorter lead times! Here’s why Glass-on-Ceramic is the superior choice:

Exceptional Durability

Glass-on-Ceramic RTD elements are highly robust, outperforming other RTD types in challenging environments.

- Every connection is fully encapsulated in glass, preventing movement in high-vibration and extreme shock situations (over 50 gRMS vibration and 750 g shock).

- Lead connections are securely anchored in glass to minimize stress concentrations, reducing the risk of breakage during assembly and operation.

Proven Reliability and Failure Avoidance

Wire-wound sensors are the industry standard in aviation, and Minco’s Glass-on-Ceramic elements are no exception.

- Our elements have accumulated millions of hours of operation in both commercial and military aviation.

- With over a century of industrial use, wire-wound sensors are a well-understood and dependable technology that helps avoid failures even in the most challenging environments.

Outstanding Stability and Predictability

Engineered for superior electrical performance, Minco’s Glass-on-Ceramic elements offer reliable stability and predictability.

- They feature a very low drift rate (inclusive drift ≤ 0.15% per year!) and exceptional thermal shock resistance (less than 0.05% change even under extreme thermal shock).

- Our sensors maintain strict adherence to IEC 60751 standards over a wide temperature range (-100 to +550 °C).

High Degree of Customization

Minco provides extensive customization options to meet specific application needs.

- Customizable features include size (diameter, length, lead length), resistance ratio (R100/R0 from 1.385 to 1.391), and base resistance (±0.04% at 0°C or other calibration temperatures).

- Customized elements available in as few as 6 weeks.

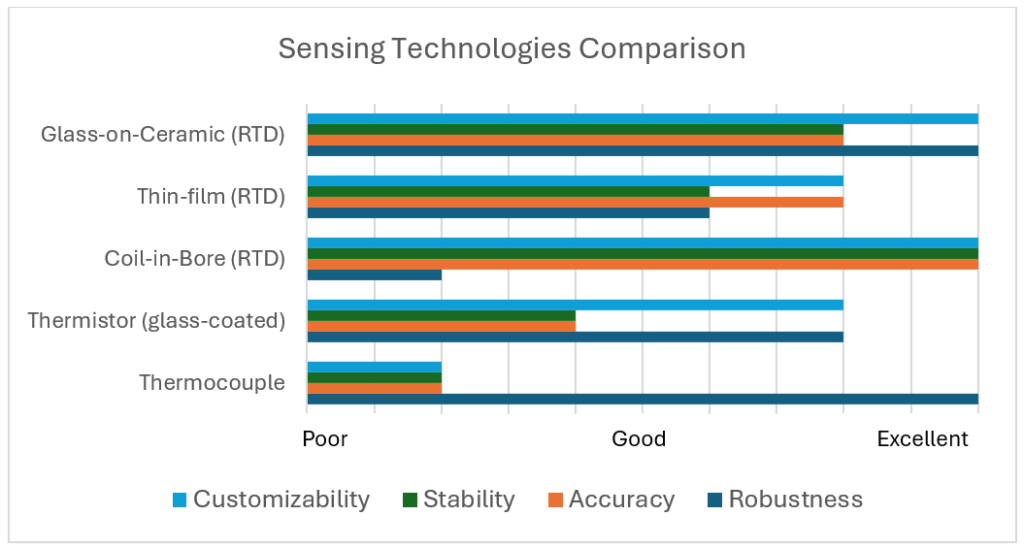

Comparison with Other Sensing Technologies:

Minco’s Glass-on-Ceramic RTD Elements provide superior robustness, stability, and customization, making them an ideal choice for demanding applications.

LET'S TALK E2E

Ready to take the next step and explore powerful design innovation?

Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance