By Katya Kaslow

Since the early 2000s, Minco has been using a strategy called Engineer-to-Engineer (E2E) to increase efficiency in our customer relationships. This strategy includes cutting out the “middleman” in hopes that engineers can work more efficiently together. It empowers our teams to work together without the need for routine involvement from management and sales, resulting in faster turnaround and fewer iterations.

Minco has been using a strategy called Engineer-to-Engineer (E2E) to increase efficiency in our customer relationships. This strategy includes cutting out the “middleman” in hopes that engineers can work more efficiently together. It empowers our teams to work together without the need for routine involvement from management and sales, resulting in faster turnaround and fewer iterations.

E2E came about as a response to two problematic areas Minco encountered. The first area was revealed during a customer survey we conducted. The survey showed that Minco’s customers were downsizing their engineering teams and keeping their primary focus on their core business. Minco found our customers needed additional engineering help from us – because of this downsizing, they were challenged to obtain materials and gain understanding of industries outside their core business. Minco’s engineers, if involved early in the process, are often able to suggest improvements to the project to smooth out supply-chain challenges and speed time-to-market.

The second challenge involved focusing the engineering teams on results, not process. By adopting the E2E strategy, Minco eliminates the “pass-it-along” game. Customers working with Minco E2E no longer need verification through our customer service and sales teams as they can work directly with our engineers instead. From the customer’s perspective, this strategy speeds up development time and provides more efficient results. From the start, our engineers can work directly with our customers’ engineers to produce their ideal product. At the same time, Minco engineers use good communication and classical project management templates to ensure all other roles are informed of progress, decisions, and action items.

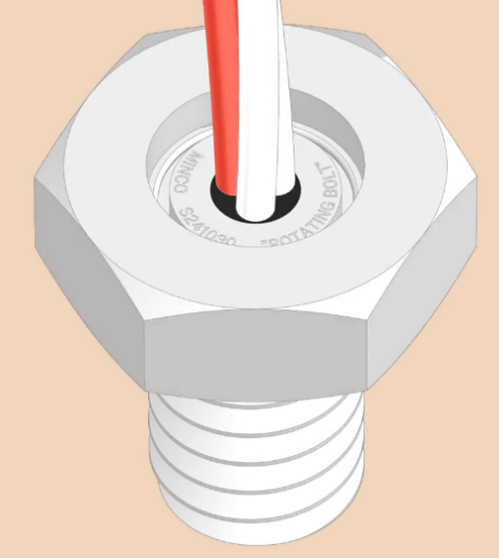

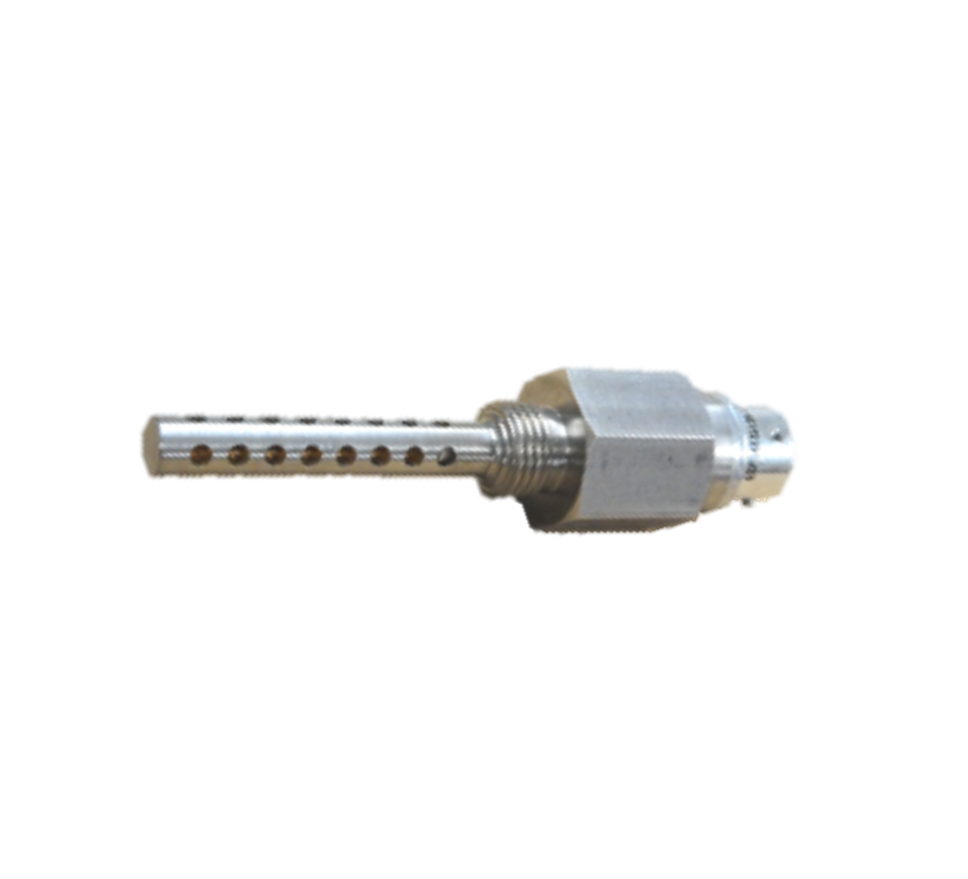

A real-life example of utilizing the E2E strategy took place when Minco worked with a company focused on veterinary pharmaceuticals. The customer needed a heater in order to increase the temperature of a reagent formula within five minutes. By encouraging the two engineering teams to meet early in the development process, we were able to reduce the price of the assembly by suggesting a less expensive heat sink—one that used vacuum die-casting rather than CNC milling in its manufacture. Had we not been working E2E that discovery would have happened later in the process and would have resulted in a longer development time and more iterations.

Contact Minco today to start working with Minco engineers E2E to find out how this strategy can save you time and money. If you want this article in a PDF format you can download it from our Product Guides page.