Pivoting from Flex to Rigid Flex Isn’t as Seamless as it Sounds

The global rigid flex printed circuit board (PCB) market is skyrocketing and more companies are expected to turn to rigid flex components in their finished

The global rigid flex printed circuit board (PCB) market is skyrocketing and more companies are expected to turn to rigid flex components in their finished

Minco’s recent acquisition of a new x-ray drill improves our ability to create smaller feature sizes while demonstrating our commitment to expanding our multi-layer flex and rigid-flex capabilities.

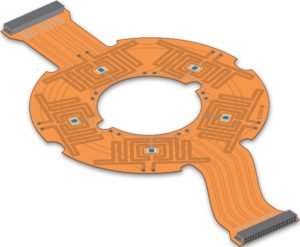

Minco’s Rigid Flex assemblies offer the advantages of both flexible cables and conventional PCBs. The rigid portions allow you to have surface mount SMT components down to 0201 on both top and bottom surfaces within the same region.

A medical device company approached Minco with a flex circuit need. They were looking to connect a heated portion of their device to their power supply.

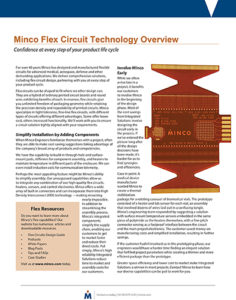

Minco’s Design Guide can be a lot of information, but it can also overwhelm someone who just wants to look up a specification or two. In the case of our Flex Circuit Technology Overview, we’ve distilled some key points and stats into a four-page PDF.

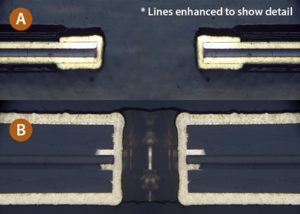

One of the primary decisions faced by our customers is whether to employ pads-only or panel plating when designing a flex circuit. You can see the two techniques in the image to theright: Figure A shows a 2-layer flex circuit with pads-only plating, whereas Figure B shows another circuit with panel plating.

In today’s competitive markets, manufacturers are always looking for ways to cut costs, slash time to market, and improve product performance. But while component buyers are price sensitive, they also look at measures like total cost of ownership, reliability, performance, and customization.

During Minco’s 62 years of operation, we have come to master a diverse — but related — set of competencies. Our Temperature Sensing and Control Solutions team makes sensors and transmitters. Our Thermal Solutions group builds heaters, and Flex makes circuits.

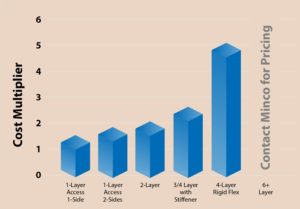

While flexible printed circuits often save money in the long term over traditional wire circuits and PCBs, they are subject to many up-front expenses that might potentially impact the bottom line. This blog post discusses a number of factors that might affect final project cost.

If you specify or design flexible printed circuits, you’ll want to check out the latest version of Minco’s Flex Circuit Design Guide. It includes sections on standard design recommendations, material tolerances, value-adds, and manufacturing tips. It’s the perfect resource for working with Minco to build a high-reliability flex circuit.

For more than 60 years, Minco has designed and manufactured heating, flex circuit, temperature sensing and instrumentation solutions for some of the world’s most demanding applications.

Thermal performance for standard and custom use cases — from environment stabilization to faster thermal cycling.

Accurately sense and measure temperature, humidity and fluid levels across a wide range of applications.

Achieve new design freedom with flex circuit solutions that improve reliability in a condensed package size.

System-matched controllers complement Minco sensors and heaters to deliver improved system accuracy.