Stator Temperature Sensors with wide Hazardous Area Certifications

Minco’s S1 stator temperature sensors have broken barriers with their wide range of hazardous area certifications.

Minco’s S1 stator temperature sensors have broken barriers with their wide range of hazardous area certifications.

Minco’s recent acquisition of a new x-ray drill improves our ability to create smaller feature sizes while demonstrating our commitment to expanding our multi-layer flex and rigid-flex capabilities.

Temperature measurement in applications as low as -120°F presents challenges on multiple fronts. With Minco’s extensive experience using our wire-wound platinum RTD (resistance temperature detector) technology, paired with 4-20mA transmitters for simple and reliable signal transmittal, the following challenges of low temperature measurement can be overcome.

When used in hazardous locations, equipment must incorporate certified temperature sensors which are tested and approved to operate safely within, and not introduce an ignition source into, hazardous environments. The challenge in specifying certified sensors is the wide range of certifications needed for different world areas.

Even during the COVID-19 pandemic, Minco still finds a way to put on fun events for its employees. On September 24th Minco’s “party squad” put on the event titled “World of Wheels, which allows employees to bring in and display any sort of machine as long as it is on wheels.

Certification requirements for Russia can be confusing to the uninitiated. Fortunately, Minco has the necessary experience and certifications to understand and provide TR CU certification (EAC mark), Metrology (= Pattern Approval) certification, Technical Passports and Poverka part verification certificates.

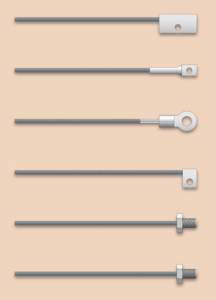

Bolt-on temperature sensors are designed for easy installation in industrial and commercial environments. The sensors can be mounted on machines, against process pipes, or embedded directly into a machined part.

This year, Minco decided to not only continue our internship program, but expand it as well. Every intern has a pivotal part in their department, having a hands-on experience that helps our business processes.

Minco Products consists of three product groups demanding separate areas of expertise and differently equipped factories. However, when we have an opportunity to create solutions that combine heaters, sensors, and flex circuits, we’re able to help our customers simplify assembly and speed time to market.

Like other trade shows in the time of COVID-19, the PCB West exhibition will be different this year. We’ll be gathering virtually September 9-10 to showcase our latest flex circuit capabilities and technology advancements.

For more than 60 years, Minco has designed and manufactured heating, flex circuit, temperature sensing and instrumentation solutions for some of the world’s most demanding applications.

Thermal performance for standard and custom use cases — from environment stabilization to faster thermal cycling.

Accurately sense and measure temperature, humidity and fluid levels across a wide range of applications.

Achieve new design freedom with flex circuit solutions that improve reliability in a condensed package size.

System-matched controllers complement Minco sensors and heaters to deliver improved system accuracy.