By Minco Staff

In most heating applications, the heating itself would be pointless without some kind of control. Typically, that process entails a controller and a sensor connected to the heater to create a feedback loop. That said, there are a number of good reasons to integrate the sensor with the heater instead of keeping the sensor as a separate component. First, this eliminates a step in assembly of the finished product. It reduces the size of the finished assembly and eliminates a set of connecting wires that could be a point of failure. It creates a more robust assembly for use in physically demanding military, aerospace, or industrial applications. It places the sensor as close as possible to the heater for accurate temperature measurement and swift response to thermal change. And while it may entail custom design and somewhat increase the cost of the heater/sensor assembly, it almost always reduces total cost of ownership and support.

be pointless without some kind of control. Typically, that process entails a controller and a sensor connected to the heater to create a feedback loop. That said, there are a number of good reasons to integrate the sensor with the heater instead of keeping the sensor as a separate component. First, this eliminates a step in assembly of the finished product. It reduces the size of the finished assembly and eliminates a set of connecting wires that could be a point of failure. It creates a more robust assembly for use in physically demanding military, aerospace, or industrial applications. It places the sensor as close as possible to the heater for accurate temperature measurement and swift response to thermal change. And while it may entail custom design and somewhat increase the cost of the heater/sensor assembly, it almost always reduces total cost of ownership and support.

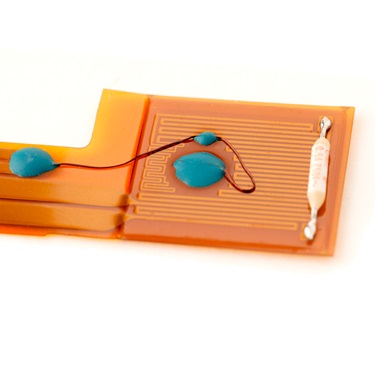

The majority of heaters with integrated sensors are etched foil, and there are several types of sensors that can be integrated into such a device. These include thermistors, wire-wound copper, platinum, or nickel-iron sensors, and chip-based platinum RTD sensors. Each generates a changing resistance that varies relative to temperature, sending a signal to the controller, which turns the heater on or off to maintain the desired temperature.

A typical integrated assembly would be an etched foil heater with a pocket left in which the embedded sensor is installed. The entire assembly would then be covered with a polyimide sheet and autoclaved to produce an assembly approximately the size of the heater alone. It would have four exposed leads, two for power and two for connection to the controller.

The choice of sensors depends on the expected temperature range, the desired toughness of the assembly, and budget. Thermistors are relatively inexpensive but only operate within a limited temperature range. An embedded epoxy-coated thermistor would be an inexpensive solution for less demanding applications. Glass-bead thermistors are more rugged and more costly. Where budget is a key issue, a surface-mounted chip or thermistor can be configured at very low cost. These would sit above the heater surface and, depending on design requirements, might need potting for protection and be slower in response to temperature change due to the insulation. Wire-wound sensors have a wider effective temperature range than thermistors but cost more. Platinum wire-wound RTDs are the most expensive option but have the widest temperature range.

Any of these options will work with a wide variety of controllers, but all of them provide an economical alternative to the assembly of separate sensors in a heating application. Each entails custom design based on the requirements of the application. But as compact, accurate, and reliable options, they are well worth consideration in virtually any heating application.

Contact us today and our engineers will help you configure an integrated component unique to your company’s needs, or find your solution on our online store.