AEROSPACE

MINCO TEMPERATURE SENSOR APPLICATIONS FOR USE IN AEROSPACE

Minco has supplied temperature sensors for aerospace applications for over 50 years. During this long history, the ultra-high reliability needs of the aerospace market have become engrained in our methods and processes. As with most good stories, it starts at the beginning – with our New Product Introduction (NPI) process. Our team based approach is a phased multi-step program highlighted by customer requirement analysis, risk assessments and design for manufacturability (DFM) reviews at the bid stage, followed by a comprehensive design and process risk analysis, leading to prototyping and post-build reviews targeted at confirming or further refining the design and processes. This meshes well with the various stages of typical aerospace projects including the kick-off meeting (KOM), preliminary design review (PDR) and critical design review (CDR) and the approach allows Minco to have fewer product development iterations, ensure robustness of the final product, and minimize delays in time to market. Finally, our project management team ensures deliverables are well understood and delivered on-time.

Minco’s advanced temperature sensor technology and manufacturing capabilities support high quality, fast responding, light weight and innovative solutions for a wide variety of aerospace applications. The most common aerospace temperature sensor is the platinum Resistance Temperature Detector (RTD) due to its wide temperature range and superior repeatability and stability over time. However, thermocouples and thermistors are also used in select applications.

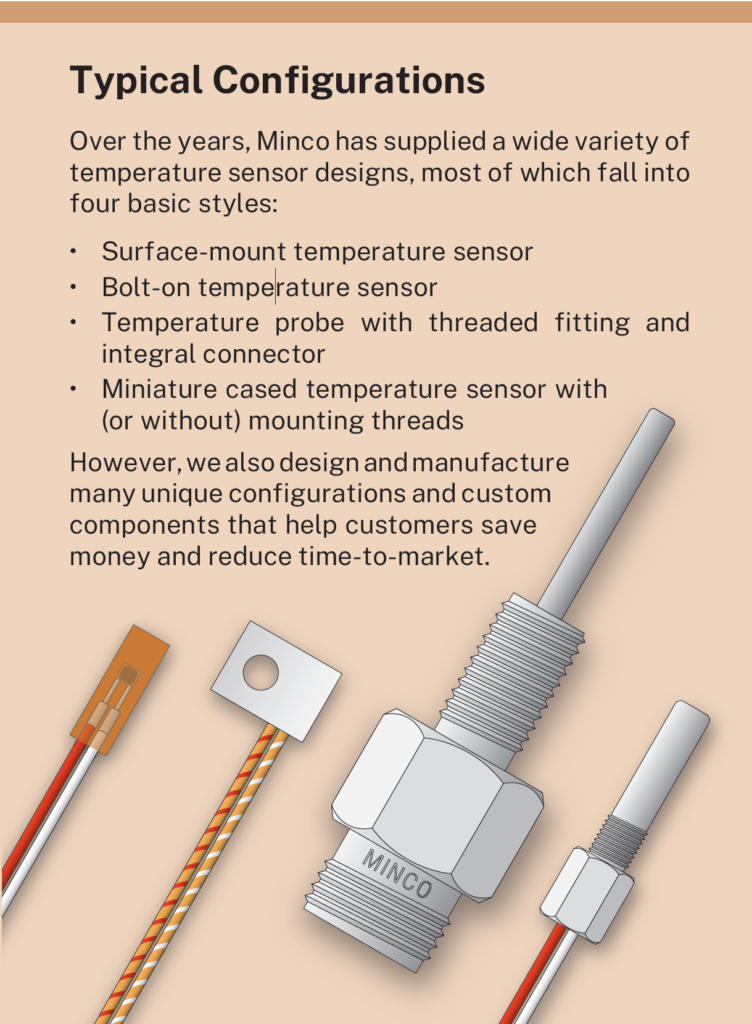

Our selection of custom and standard RTDs, thermocouples and thermistors are available in a range of configurations to meet specific application requirements for installation, performance, and reliability. The temperature sensor construction has a direct impact on the sensor’s measurement stability, resistance to vibration and shock, thermal time response, resistance to corrosive media and other key performance characteristics. Requirements for our temperature sensors may include:

• Single, dual or triple sensing elements

• RTD Temperature ratings up to 600 degrees C

• Time response values below 1 second

• RTCA DO-160G requirements including vibration, shock, altitude, temperature variation and humidity.

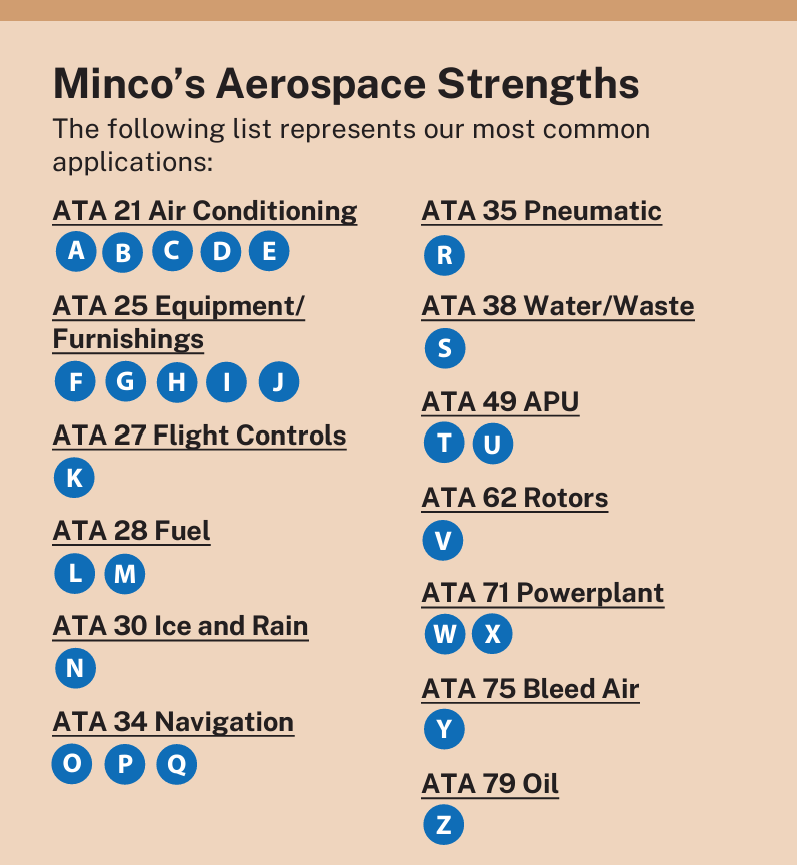

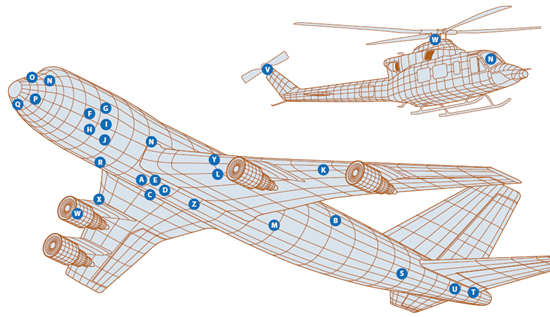

Minco aerospace temperature sensor applications are numerous and found throughout various aircraft systems. Minco sensors are found in the following Air Transport Association (ATA) chapters: Air Conditioning/Air Management, Galley Food and Beverage Equipment, Flight Controls, Fuel, Hydraulic Power, Ice and Rain Protection, Navigation, Water/Waste, APU, Rotors, Powerplant and Bleed Air. Refer to specific applications on the following pages.

Minco’s aerospace offerings are bolstered by our experience in other markets. We integrate knowledge gained from the small, fast responding needs of sensors for medical diagnostics equipment with the cannot-fail aspect of nuclear power sensor applications. Moreover, we have equipment and processes in house, normally not available to a temperature sensor manufacturer from our instrumentation, flexible heater and flexible circuit product lines.

MINCO OFFERS SENSOR SOLUTIONS FOR EVERY PART OF THE AIRCRAFT

Minco aerospace customers regularly ask for “lighter, faster and smaller” products. We are able to meet these needs by leveraging our decades of design experience and proprietary manufacturing capabilities. The end result is a solution suited to meet your application’s required temperature range, mounting needs, and space and weight restrictions. Our experience in supplying temperature sensors on aircraft reaches virtually all major and many smaller aircraft platforms and is shown on the diagrams below.

INTEGRATE AND SAVE

During Minco’s six decades of operation, we have come to master a diverse—but related—set of competencies. In addition to our extensive portfolio of aircraft temperature sensors described in this brochure, Minco supplies numerous custom heaters, heater assemblies and flexible circuits in many for applications such as:

• De-icing heater for airflow sensor

• Galley and floor heaters

• Water and waste-water heaters

• Electrical wing de-icing heaters

• Cockpit display heaters

• Business class seat heaters

• Flex circuits for in-seat entertainment system

• Flex circuits for instrumentation and control systems

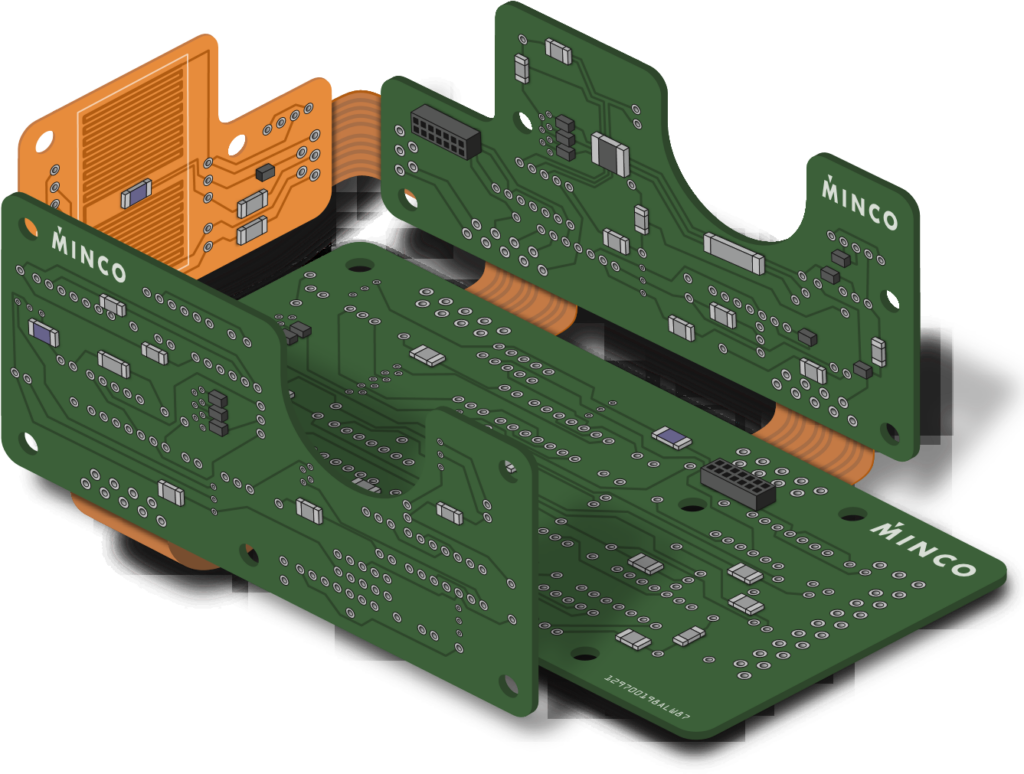

Many challenges brought to us require advanced expertise that spans all of Minco’s engineering disciplines. Critical systems like avionics, satellites, and medical imaging devices—the purpose of which is too important to be allowed to fail—all benefit from Minco’s broad array of specialties. Our application solutions are reliable, innovative, practical, and often include the integration of thermal, flexible printed circuit board (PCB), as well as sensor and instrument design, into a single package.

When Minco Engineers work closely with customers on a project, they often can make cost-saving suggestions. One example might be the wires or flex leads connecting the heater

to other components in the enclosure. Old-fashioned wiring bundles pose installation difficulties due to their bulk and the possibility of miswiring the rig. By combining the various wires into a flat package and adding connector plugs, wiring challenges are eliminated—it’s impossible to connect the plugs the wrong way.

Greater space efficiency and lower cost to market make Integrated Solutions a winner in most projects. Contact Minco to learn how our diverse capabilities can be put to work for you.

CERTIFICATIONS

Minco’s Quality Management System complies with a variety of market-specific standards. Minco’s experience in each of our market areas enables us to understand their unique quality requirements and what it takes to meet them. We work closely with national and international standards bureaus to develop manufacturing and quality assurance procedures. Our Quality Management System has been audited and certified compliant with these internationally recognized standards. In addition, individual products also possess a variety of product-level certifications and accreditations. To view all certifications that Minco carries, please visit our list on Minco.com.

Minco’s core quality certifications are noted below:

AS9100/EN9100: 2016

ISO 9001:2015

Nadcap: Electronics AC7119 and AC7119/2

CASE STUDY: THERMALCLEAR WINDOW HEATING

WANT MORE CASE STUDIES AND COLLABORATION TIPS?

Check out our integration ebook here

COLLABORATE WITH

ENGINEERS WHO GET IT

No matter the design challenges, Minco engineers bring best practices from hundreds of similar projects worldwide to help our partners plan and design the best solutions for their aerospace projects.

LET'S TALK E2E

If you and your engineering team are ready to take the next step and explore powerful design innovation, Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance.