By John Baichtal

By John Baichtal

We’ve had the opportunity to build solutions for countless companies over the years, and we’ve earned their trust not only because of the quality of the components we manufacture, but also our robust and thoughtful New Product Introduction (NPI) process.

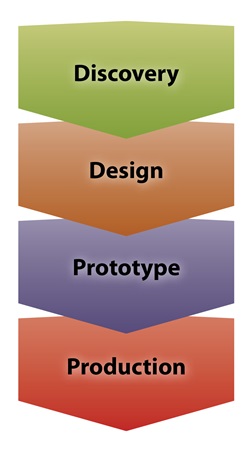

Our team-based NPI approach allows for initial upfront design for manufacturability (DFM) analysis at the bid stage, followed by a comprehensive design and process risk analysis. This detailed NPI approach allows Minco to have fewer product development iterations, ensure robustness of the final product, and minimize delays in time-to-market. Minco’s NPI process consists of a phased approach highlighting 20 key steps.

DISCOVERY

1. Customer Requirements Analysis: We can’t suggest a solution without first understanding the problem. The first step involves collaboration between Minco and our customers to gain an understanding of the application requirements and the problems our customers face. This may include review of a quote package, or even an Engineer-to-Engineer (E2E) conference call or site visit. Internally, Minco engineering will prepare a Customer Requirements Document (CRD) that establishes the parameters of the project. Our CRD is unique to Minco in that we periodically update the process to reflect information and techniques learned company-wide.

2. Documentation Review: During the initial stage of the NPI process we will study your specifications, Bill of Materials (BOM) and other critical to quality (CTQ) requirements. The most common problem we encounter at this stage is incomplete information – missing circuit views, operating conditions, tolerance expectations, and design flexibility. This also gives us the opportunity to spot early supply or design issues that could affect manufacturability.

3. Risk Assessment: Design rule checks – Are customer requirements attainable? Are materials new to us or that we do not ordinarily stock? Do we need to develop new tooling and create the corresponding procedures around them?

DESIGN

4. Record Keeping/Documentation Creation: Alongside the creation of the final design are the documents used for manufacturing. Minco operating procedures call for revision-controlled specification drawings, manufacturing instructions, and acceptance test requirements; user manuals and installation instructions are developed as needed. For security and compliance purposes we segment our file storage so only approved employees with proper citizenship and clearance can access client documents.

5. Supply Chain Analysis: Minco keeps vast quantities of raw materials on hand, a necessity given the wide variety of sensors, heater, and flex circuits that we manufacture. When sourcing a new component, our extensive supplier contacts allow us to assure the best possible option; we often suggest alternative materials and components that may provide a cost or lead time advantage for our customers.

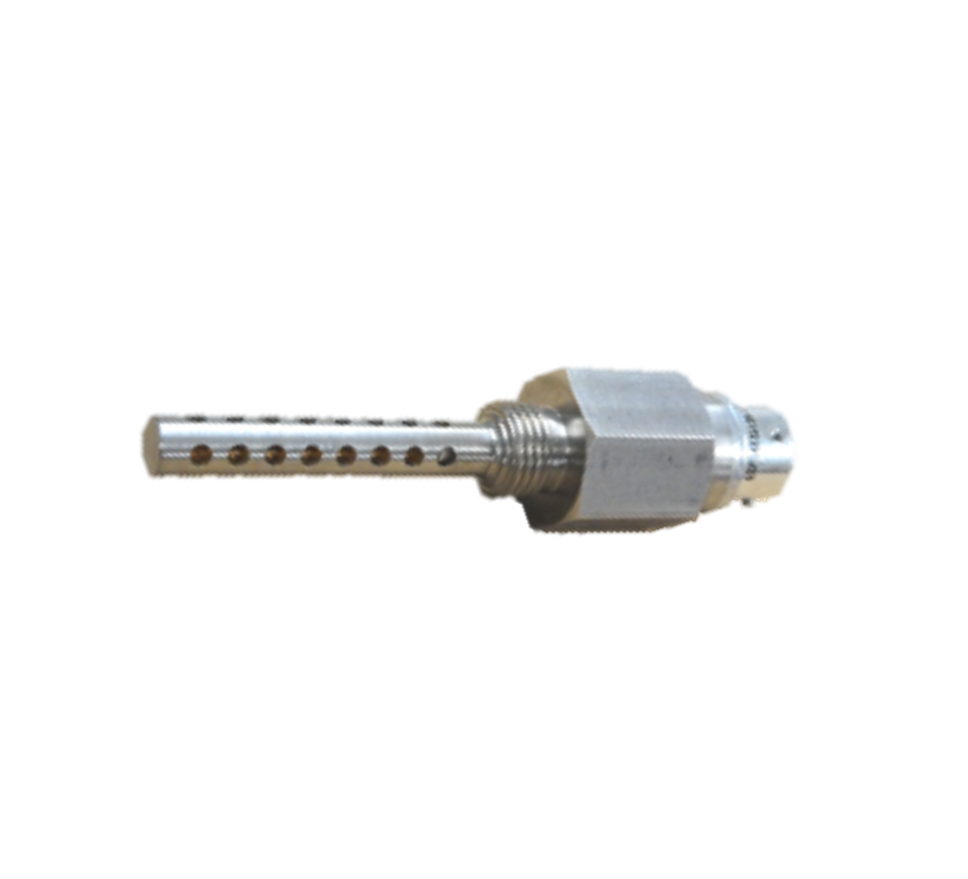

6. Integrated Solution Review: Perhaps the most beneficial portion of the design process is when Minco engineers are able to suggest changes and efficiencies in the design. For instance, when adding a heater to thermally stabilize an object, it might make sense to include a flexible interconnect, or to add a RTD or thermistor to the assembly to measure its temperature. We call these combined products Integrated Solutions. The company has been in business for over sixty years and has developed a number of core competencies that can often be combined to create these value-added assemblies.

7. Design for Manufacturability (DFM) Analysis: Minco stays focused on the end result by steering the design toward a readily-manufacturable solution. Sometimes it’s as simple as ensuring that the maximum-possible panel space is utilized, or that a complicated circuit doesn’t pose unusual challenges for our assemblers. One of the advantages of manufacturing in-house is that our engineers can build mistake-proofing procedures and efficiencies into the production process.

8. Regulatory Compliance: Minco has been certified compliant with countless standards, including industry certs such as AS9100 as well as environmental guidelines like RoHS. Minco monitors the ongoing project to ensure its compliance with appropriate standards.

9. Material/Process Testing: Before the project parameters are finalized, we test and validate any new material and process to ensure they are suitable for the design.

10. Design Review: The final step of the Design phase is a comprehensive review of all specifications, drawings, processes, and other criteria relating to the design.

PROTOTYPE

11. Develop Tooling and Tool Programs: Minco’s engineers begin developing the laser programs, drill/route programs, die lines, PCB gerbers, and assembly/test fixtures that will not only help Minco create the prototypes but will ultimately be used as part of routine production of the part.

12. Prototype Assembly: The component is built by our prototype technician team. Most, if not all of the processes used to manufacture prototypes utilize standard production procedures, ensuring the product will be suitable for future launch into production. Our team employs the same equipment and workspaces that our assemblers will use once the part reaches production, ensuring that there are no surprises during the process.

13. Testing/Simulation: All prototypes receive a thorough acceptance test inspection including verification of any CTQ requirements. In addition, Minco has a suite of simulation programs available to help solve thermal and electrical challenges.

14. Prototype Post-Build Review (PBR): Having completed the prototype, Minco’s team updates assembly instructions and procedures to prepare for the production process.

PRODUCTION

15. Production First-Run: Any updates or production volume tooling introductions will be processed through a “first-run” manufacturing build, during which the production operators will complete the first build using final manufacturing processes and equipment.

16. Inspection: The finished parts receive a thorough inspection according to Minco’s quality procedures, which may include dielectric strength to verify electrical insulation or resistance measurement to verify accuracy.

17. First-Run PBR: Based on feedback from the first production run, Minco identifies any final refinements appropriate for the assembly instructions and procedures.

18. Launch: With all action items completed for the NPI process, the part is now ready for final launch to production. The part is manufactured following statistically-validated production processes and using DOE methodology to reduce variation. Additionally, Lean principles are implemented throughout the design and manufacturing processes.

19. Ramping Up Production: Thanks to Minco’s ability to be involved in the entire design process, we are able to quickly transition from building prototypes to manufacturing the final component.

20. Supply Chain Management: During the production run, Minco actively manages the supply chain to address demand fluctuations, cost targets, and part obsolescence.

Contact Minco today to learn how we can make your next New Product Introduction a success. Alternatively, you can download a PDF version of this file from our Product Guides page.